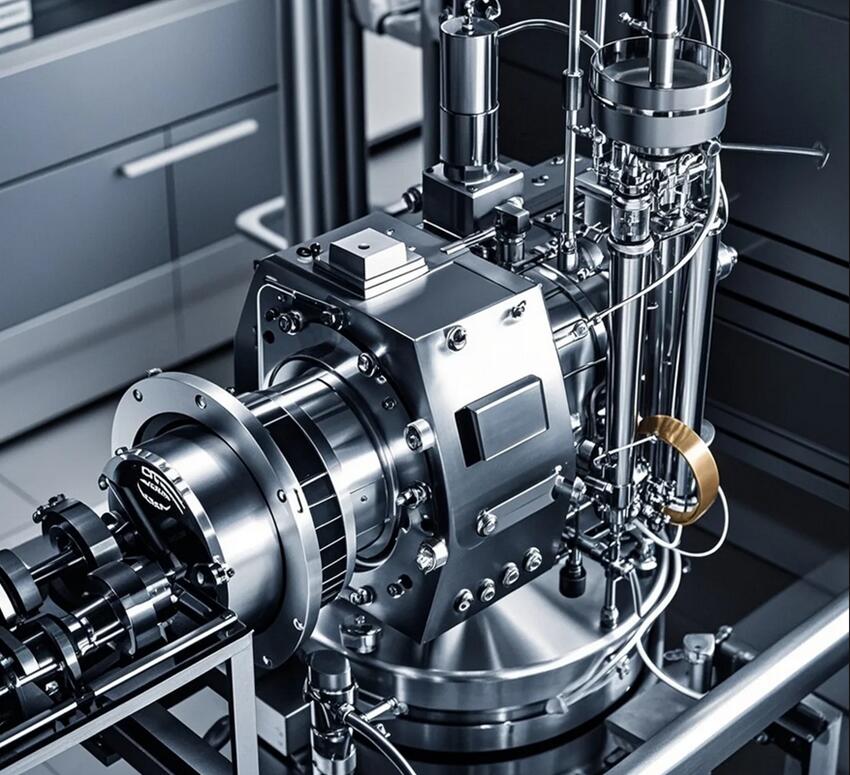

In the world of mass spectrometers, the vacuum environment is the cornerstone for obtaining accurate data. And the ion pump is the key equipment for creating and maintaining this ultra-high vacuum environment.

As a clean and oil-free vacuum acquisition device, the ion pump can reduce the pressure in the analysis chamber of the mass spectrometer to an extremely low level (usually reaching 10 ⁻⁶ to 10 ⁻¹¹ mbar), ensuring that ions are not disturbed by gas molecules during flight and guaranteeing measurement accuracy and reliability.

Why does a mass spectrometer require an ion pump?

The core of mass spectrometry analysis is to convert sample molecules into ions and separate them according to the mass to charge ratio (m/z). If the vacuum degree is insufficient, residual gas molecules will collide with sample ions, resulting in broadening of peak shape, decreased resolution, increased background noise, and even inability to detect low abundance components.

Traditional oil diffusion pumps pose a risk of oil return, which may contaminate the ion optical system and reduce detection sensitivity. The ion pump completely solves this problem, and its completely oil-free working mode provides a clean environment for mass spectrometry analysis.

The role of ion pumps in various mass spectrometry applications

The application scenarios of ion pumps in mass spectrometers are diverse, especially outstanding in the following fields:

Electron microscopy combined technology: In scanning electron microscopy (SEM) and focused ion beam (FIB-SEM) systems, the dry front-end pump works in combination with the ion pump, which is resistant to xenon/gallium ion source sputtering pollution and significantly extends the maintenance cycle.

Technological Evolution: Integration and Intelligence

To meet the demand for miniaturization and integration of mass spectrometers, the control system of ion pumps is also constantly evolving. Modern solutions integrate high-voltage power supply and vacuum control into one, and the high-voltage module integrated onto a single circuit board can provide 0-7kV high-voltage output for ion pumps, and achieve vacuum degree acquisition and intelligent control of system components through embedded processors.

The integrated design of ion pumps not only reduces their size, but also enables them to easily adapt to silent laboratory environments due to their zero vibration and low power consumption characteristics, helping laboratories reduce operating costs.

Although ion pumps do not directly generate detection signals, they are the behind the scenes contributors to the high resolution and sensitivity of mass spectrometers. From life sciences to material analysis, from environmental monitoring to industrial production, ion pumps continue to provide a solid and clean vacuum foundation for mass spectrometry analysis, silently pushing the boundaries of scientific exploration and quality control.