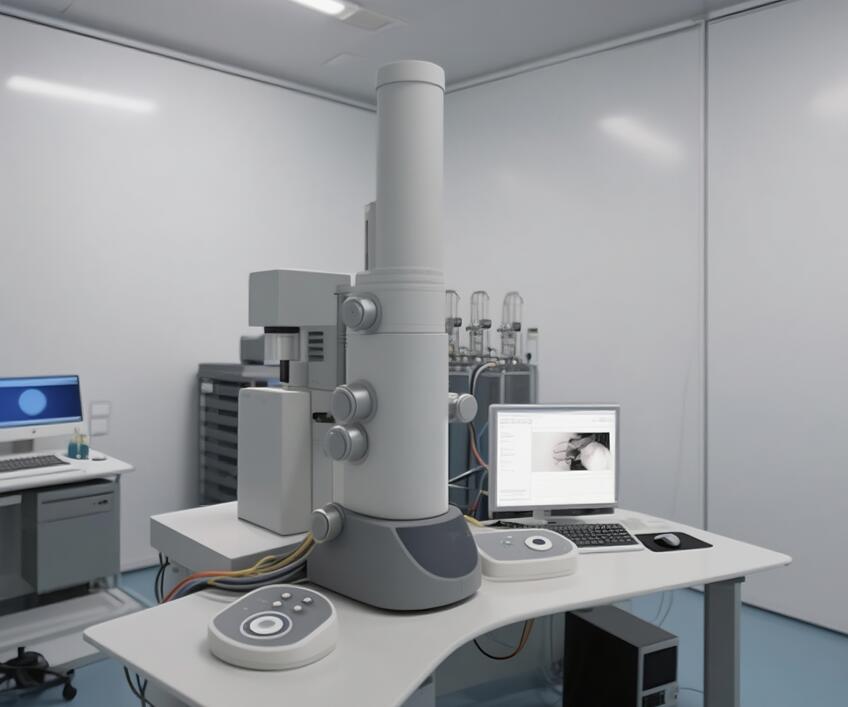

In the exploration of the microscopic world, scanning electron microscopy (SEM) and transmission electron microscopy (TEM) are like the "eyes" of scientists, and ion pumps are one of the key components to ensure the clarity and brightness of these "eyes". Although it does not directly image, it is the unsung hero that maintains the high-performance operation of electron microscopes.

In the world of mass spectrometers, the vacuum environment is the cornerstone for obtaining accurate data. And the ion pump is the key equipment for creating and maintaining this ultra-high vacuum environment.

Ion pumps, as a pollution-free and highly extreme vacuum obtaining equipment, play a key role in cutting-edge scientific research and industrial fields. It maintains a clean ultra-high vacuum (UHV) environment by ionizing and capturing gas molecules, which is crucial for the normal operation of many precision equipment.

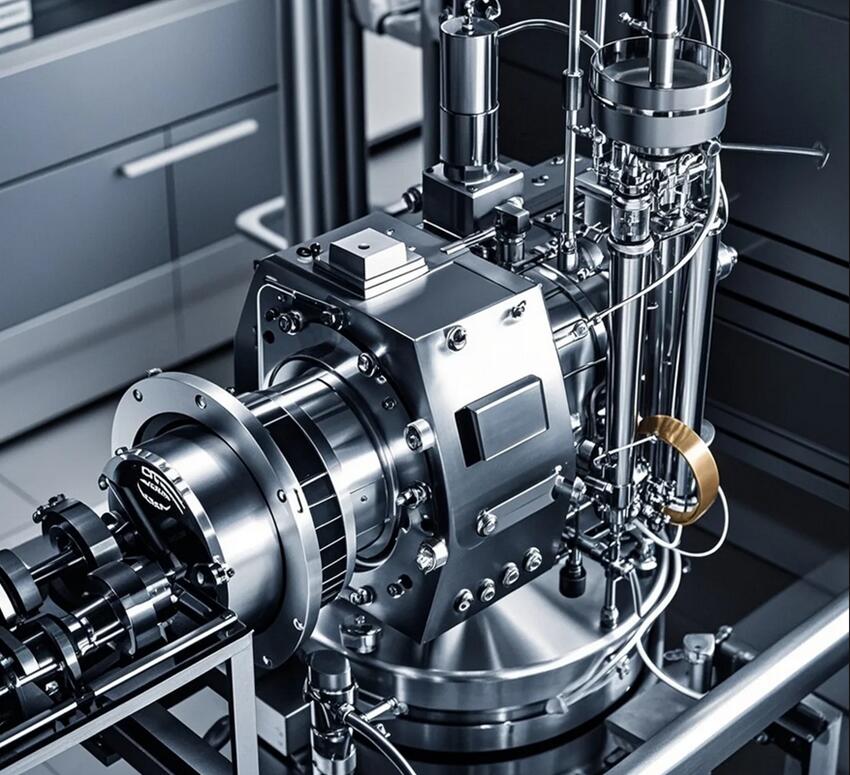

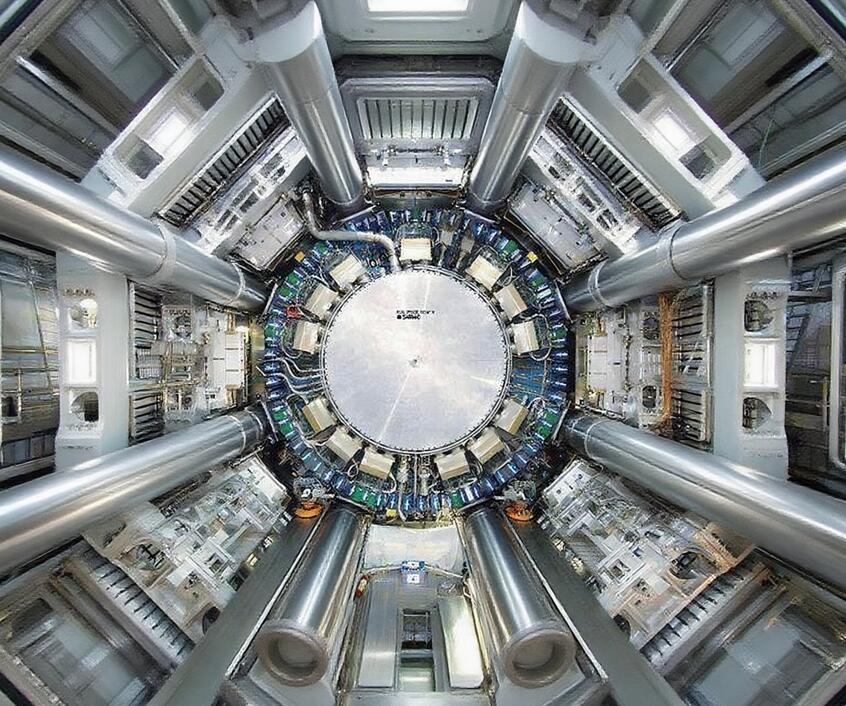

As an oil-free and clean ultra-high vacuum acquisition device, ion pumps play a core role in electron gun systems. The electron gun is a key component of high-end equipment such as electron microscopes, particle accelerators, and free electron laser devices, and its performance directly depends on the high vacuum quality of the working environment. The ion pump maintains the vacuum degree through a non evaporative suction mechanism, avoiding oil contamination and ensuring the stability of electron emission and acceleration processes.

Ion pump is one of the key equipment for obtaining and maintaining ultra-high vacuum (UHV, usually referring to pressure below 10 ⁻⁸ mbar) and even extremely high vacuum (XHV) environments. It relies on on-site discharge to ionize gas molecules, and permanently captures gas molecules through chemical adsorption and physical burial mechanisms, thereby achieving clean, oil-free, and vibration free vacuum maintenance. This characteristic makes it play a core role in many cutting-edge technological fields that require extremely high vacuum quality, cleanliness, and stability.

As a vacuum device capable of achieving ultra-high vacuum, ion pumps play an indispensable role in high-end technology fields. Its characteristics of no oil pollution, quiet operation, and long-term stable operation make it particularly suitable for space exploration and communication technology fields that require high cleanliness and reliability.

In extreme ultraviolet (EUV) lithography technology, ion pumps play an indispensable role as key high vacuum acquisition equipment. EUV lithography machines need to operate under extreme ultraviolet light with a wavelength of 13.5nm, which is easily absorbed by air. Therefore, it is necessary to create and maintain a very high vacuum environment in its optical path and light source area (usually requiring 10 ⁻⁸ mbar or even lower) to eliminate the interference of particles and gas molecules and ensure the accuracy of the lithography process.

The space experimental station is an important platform for human space science research, and maintaining the ultra-high vacuum environment inside and specific experimental equipment is crucial. As a pollution-free and highly reliable vacuum acquisition device, ion pumps play an irreplaceable role here.

As an efficient vacuum device, ion pumps play an indispensable role in the field of medical imaging, especially in high-precision medical equipment such as magnetic resonance imaging (MRI) and radiographic imaging, providing key technical support for maintaining the core stability of the imaging environment.

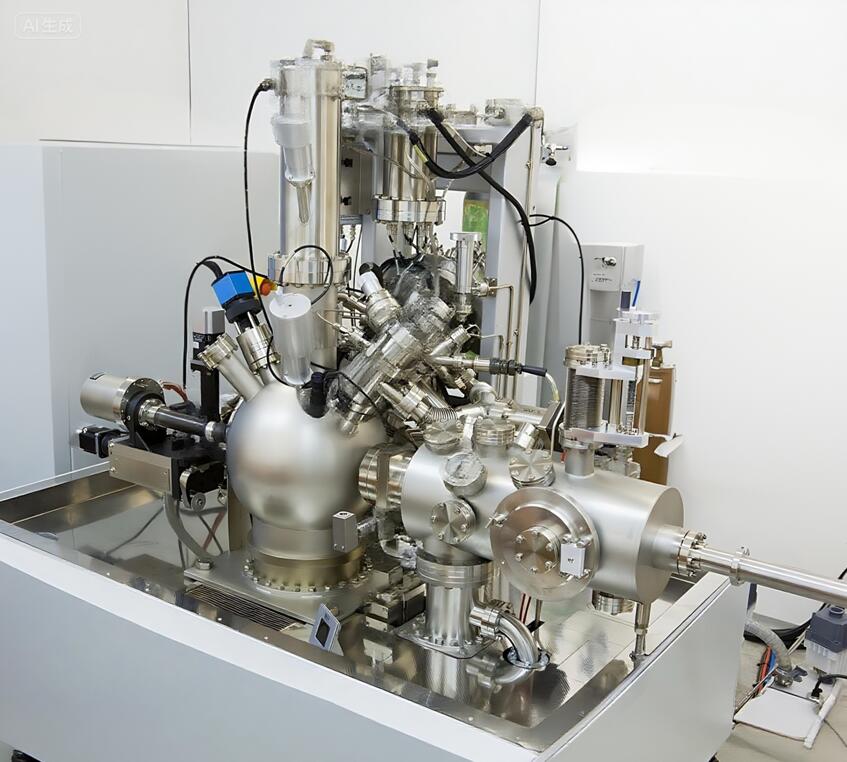

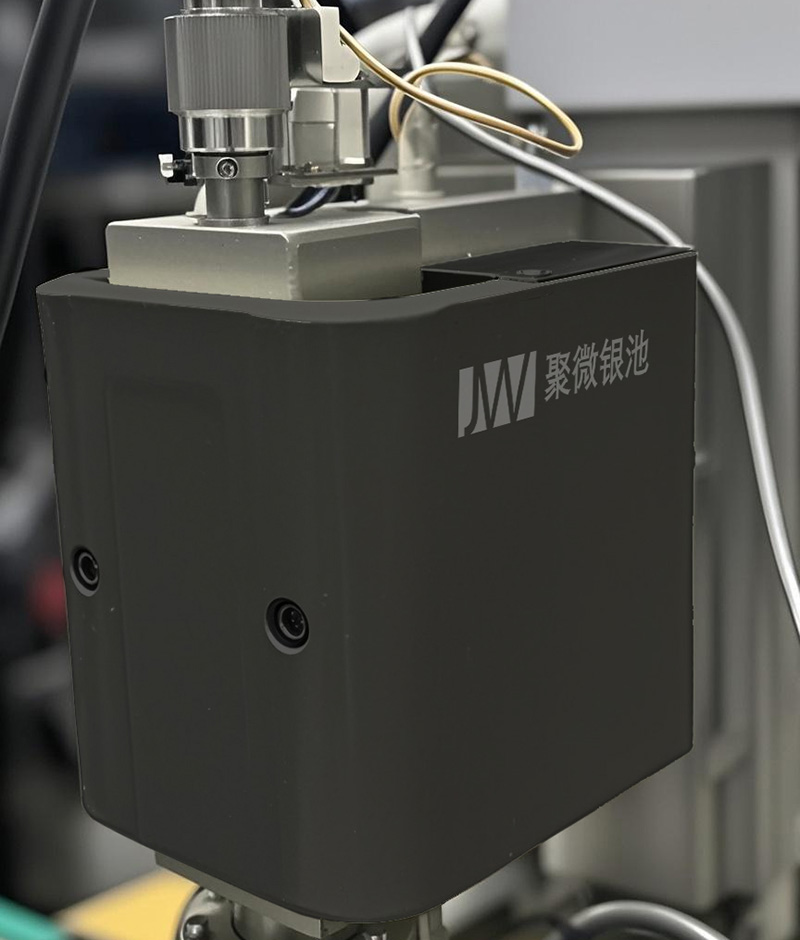

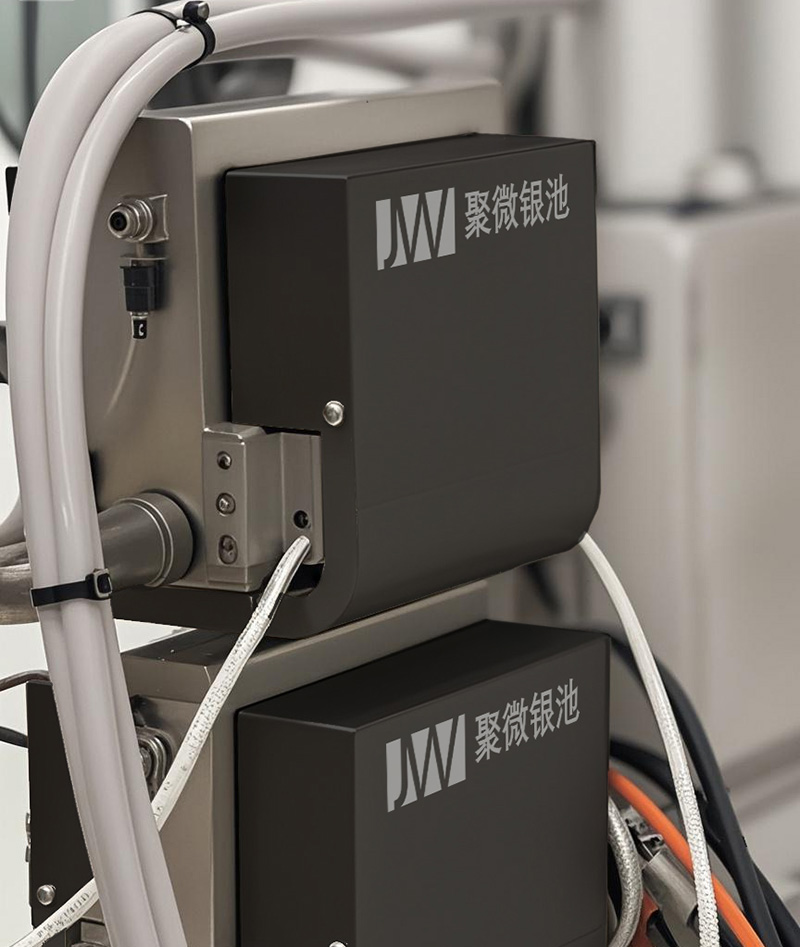

Our company's independently developed JWS-F series ion pump has successfully passed the rigorous validation by a leading domestic semiconductor equipment manufacturer, supporting its FIB-SEM dual-beam analysis platform and providing stable ultra-high vacuum performance. The product's performance rivals top-tier international brands, with a 75% shorter lead time and a 30% cost reduction. This enables customers to significantly enhance supply chain security and effectively mitigate the risk of foreign "bottlenecks," establishing a successful model for the localization of high-end vacuum components in domestic semiconductor equipment.

Our company has tailored three specialized ion pumps for a leading TEM scientific instrument company. After rigorous testing, the ultimate vacuum is ≤ 1 × 10 ⁻⁸ Pa, which directly replaces the original imported model. Our company has now been included in the supply chain list for the TEM product of this customer. The procurement amount has been expanding year by year, the product delivery time has been shortened by 40%, and the cost has been reduced by 50%. The localization rate of key components has increased from 60% to 90%. Customer feedback: "We are no longer afraid of overseas supply interruptions. Domestic pumps make us feel at ease

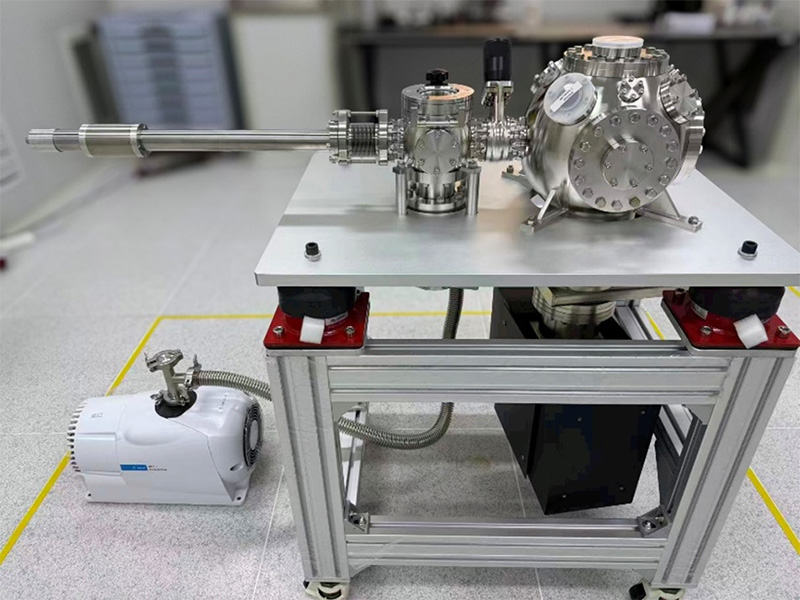

In the National Natural Science Foundation project "Fiber End Quantum Dot Growth", our company has customized a set of ultra-high vacuum solutions for a key university. Due to the tight project timeline and high performance indicators, we quickly formed a joint research and engineering team, completed the prototype design in a short period of time, and passed on-site verification in one go. The vacuum degree far exceeded expectations, providing an unprecedented clean environment for the precise growth of quantum dots.