In extreme ultraviolet (EUV) lithography technology, ion pumps play an indispensable role as key high vacuum acquisition equipment. EUV lithography machines need to operate under extreme ultraviolet light with a wavelength of 13.5nm, which is easily absorbed by air. Therefore, it is necessary to create and maintain a very high vacuum environment in its optical path and light source area (usually requiring 10 ⁻⁸ mbar or even lower) to eliminate the interference of particles and gas molecules and ensure the accuracy of the lithography process.

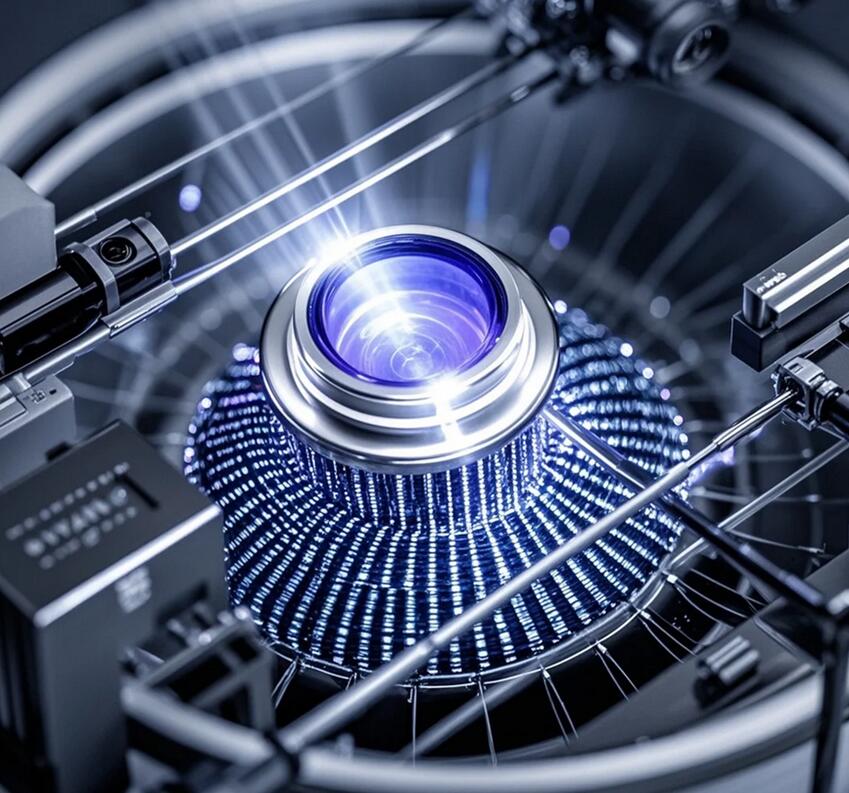

In the optical system of EUV lithography machine (including illumination system and projection objective), ion pump can provide clean vacuum without vibration and oil pollution. The design without moving parts avoids the generation of micro vibrations, which is crucial for ensuring the stability of optical components and the precise transfer of lithography patterns. At the same time, the fully dry oil-free design of the ion pump completely eliminates the pollution of hydrocarbons and protects the surface of expensive optical components.

Corrosion resistant ion pumps are particularly important in the face of process by-products generated by EUV light source systems (such as laser plasma light sources), such as debris and other active gases that may be generated after tin droplet evaporation. These pumps are treated with special coatings that can effectively remove and withstand corrosive gases, extending the maintenance cycle and service life of the equipment.

With the development of EUV lithography technology towards higher power light sources and the exploration of new light source technologies such as free electron lasers (EUV-FEL) that may be used in the future, more extreme requirements have been put forward for the stability and cleanliness of vacuum environments. The ion pump technology is also continuously evolving.

In summary, ion pumps ensure the efficient transmission of EUV light and the accuracy of lithography processes by providing a stable and clean high vacuum environment, and are the behind the scenes contributors to the sustained development of advanced semiconductor manufacturing.