Ion pump is one of the key equipment for obtaining and maintaining ultra-high vacuum (UHV, usually referring to pressure below 10 ⁻⁸ mbar) and even extremely high vacuum (XHV) environments. It relies on on-site discharge to ionize gas molecules, and permanently captures gas molecules through chemical adsorption and physical burial mechanisms, thereby achieving clean, oil-free, and vibration free vacuum maintenance. This characteristic makes it play a core role in many cutting-edge technological fields that require extremely high vacuum quality, cleanliness, and stability.

Ion pumps are indispensable in basic scientific research facilities. For example, in particle accelerators, synchrotron radiation rings, and beamlines, the system needs to operate at a constant low pressure for a long time and effectively process mixed gases (including inert gases and hydrogen). Ion pumps using tantalum cathodes or ion pumps with more balanced pumping capabilities perform well in such applications. They can stably maintain a maximum vacuum below 10 ⁻¹¹ mbar and effectively avoid interference from pressure fluctuations on particle beams or experimental results.

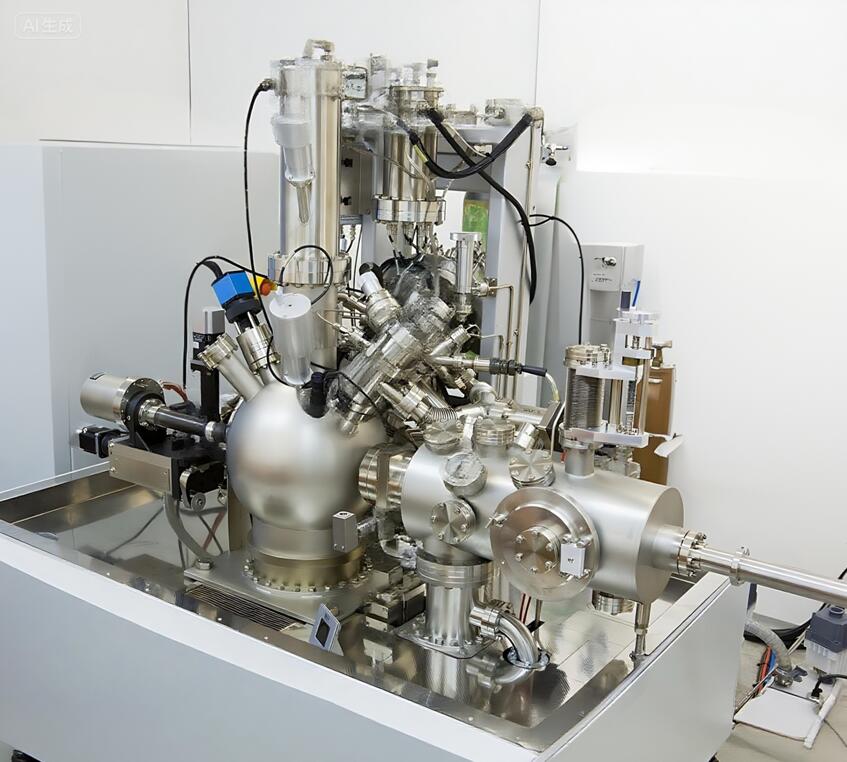

The sample cavity of surface analysis systems (such as X-ray photoelectron spectroscopy, low-energy electron diffraction, etc.) and high-resolution electron microscopes is another important application area of ion pumps. These devices require a vacuum environment that is not only clean and pollution-free, but also completely vibration free to prevent sample image blurring or analysis signal distortion. The diode type ion pump is widely used in such precision instruments due to its high pumping speed for hydrogen gas and absolute vibration free characteristics.

Ion pumps also play an important role in some key processes in the semiconductor industry. For example, an ion implantation machine requires precise control of the ion beam under ultra-high vacuum, and any vibration may cause deviations in the injection dose. The vibration free vacuum environment provided by the ion pump meets this demanding requirement. In addition, ion pumps can also be used in vacuum systems of electron beam lithography and certain thin film deposition equipment.

Large interferometers, such as gravitational wave observation devices, are a typical example of ion pump applications. This type of equipment has extremely strict requirements for vacuum degree, with a maximum vacuum of better than 10 ⁻¹¹ mbar, and requires the vacuum pump to have low leakage current and low magnetic field interference characteristics to avoid affecting precision measurements. High pumping speed ion pumps (such as 500 L/s or higher) have become the preferred choice for such systems.

It is worth noting that ion pumps usually need to be used in conjunction with molecular pump groups, which provide the necessary pre vacuum for startup (usually better than 10 ⁻⁷ mbar). In order to further enhance the pumping capacity of gases such as hydrogen and achieve lower ultimate vacuum, ion pumps are often combined with titanium sublimation pumps or non evaporative suction pumps to form composite pump sets, which have become standard configurations in many modern large-scale scientific research facilities.

In summary, ion pumps, with their unique performance advantages, continue to provide fundamental and critical support for technological progress in numerous ultra-high vacuum applications ranging from cutting-edge scientific research to high-end industrial manufacturing.