Ion pumps, as a pollution-free and highly extreme vacuum obtaining equipment, play a key role in cutting-edge scientific research and industrial fields. It maintains a clean ultra-high vacuum (UHV) environment by ionizing and capturing gas molecules, which is crucial for the normal operation of many precision equipment.

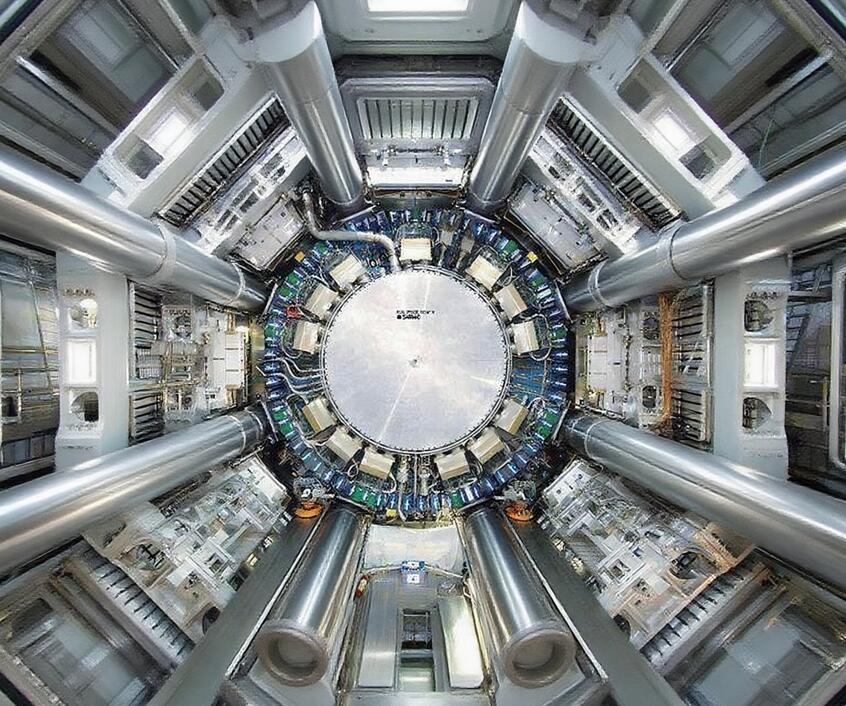

In the field of particle accelerators, ion pumps are essential equipment for maintaining vacuum operation. Taking the large facility of the European Organization for Nuclear Research as an example, ion pumps are extensively used in various accelerator rings and beamlines. From early intersecting storage rings to large positron electron colliders, and now to the Large Hadron Collider, ion pumps continue to provide ultra-high vacuum for superconducting magnet rings up to 27 kilometers long. For accelerators, extremely high vacuum can effectively reduce collisions between particle beams and residual gas molecules, ensuring stable beam transmission and smooth experimental progress. Different types of ion pumps are usually selected for accelerators that may encounter different gas components (including inert gases and hydrogen), which can more effectively handle mixed gases and provide stable pumping performance.

In the focused ion beam (FIB) system, the ion pump also plays a central role, with its main task being to maintain the high vacuum required for the electron (ion) gun and sample chamber. FIB technology focuses high-energy ion streams into nanoscale beams for microfabrication, imaging, and sample preparation (such as preparing transmission electron microscopy samples). This system has extremely high requirements for vacuum environment, and any residual gas may cause ion scattering, contaminate the sample, or lead to unnecessary discharge. Ion pumps can maintain the required high vacuum level (usually on the order of 10 ⁻⁷ to 10 ⁻⁹ Pa) cleanly, minimizing the interaction between ion beams and gas molecules, thereby ensuring processing accuracy and imaging quality.

The value of ion pumps in these applications stems from their unique advantages: clean and oil-free, avoiding pollution from hydrocarbons; High ultimate vacuum degree, up to 10 ⁻¹¹ mbar or even lower; Quiet and vibration free operation; And no maintenance is required. These characteristics make it a reliable cornerstone for supporting cutting-edge scientific research and high-end industrial manufacturing.

The ion pump technology itself is also constantly evolving, for example, by combining sputtering ion pumps with non evaporative absorbers to form composite pumps with stronger pumping performance, in order to meet more demanding application requirements in the future.